|

- Drill holes at the positions where you want

to install the computer ventilators. Glue the ventilators

to the box. I have positioned them on the short (right in

picture) side of the tray. Glue the computer ventilators to

the box, taking care to position them correctly respective

to the required air flow. Connect them up electrically and

check if they work. In my case, the ventilators suck out the

air and are therefore located at the air outlet position.

I recommend you to do this as well, as it will create underpressure

and keep the lid on top of the box, instead of maybe almost

blowing it of... Of course, this construction is far from

light safe, so use black matting carton, glue and gaffer tape

to create a light-tight air outlet. The light block is constructed

to require air (and light) to travel through two full U-turns,

effectively cutting out all light. Make sure you've checked

electric connections for safety and function before you start

constructing the outlet!

The drying box with the lid removed, air

flow is left to right in this image, with the computer ventilators

hidden in the right outlet protrusion. Notice the vacuum cleaner

filter covering up the left-side air inlets.

Drying box with foam board lid on top,

ready for drying session. This construction is fully light

safe, and can be left for days in the light, if needed, without

risk of fogging the paper.

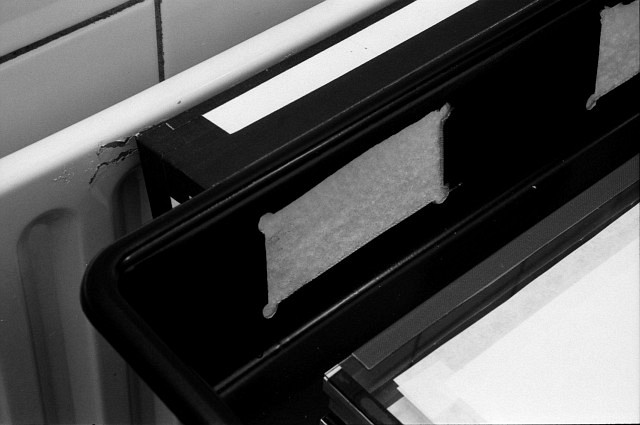

- The air inlet: Drill four holes and use a saw

to cut a square hole. To avoid weakening the tray to much,

I have used two holes instead of one large one. Use the vacuum

cleaner filters to cover them up and keep dust out, see the

first picture above. Again use matting carton to create an

effective light-block around the inlet, taking care to maintain

free air flow.

Detail of the air inlet. Note the vacuum

cleaner filter covering up the inlet to keep dust out. Also

note the protrusion on the outside of the tray. This is the

light-block created using matting carton.

Detail of the air outlet. Computer ventilators

are hidden behind the drilled holes in this picture.

Detail of the air outlet. Computer ventilators

hidden in construction of light block, that uses two full

U-turns to block out light and guide the air flow. Air flows

out through the visible opening. Also notice the stacked coated

papers inside the drying box.

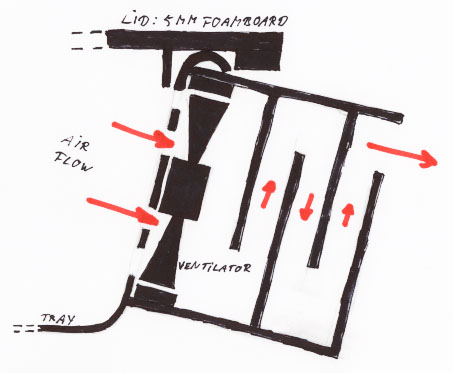

Cross-sectional view of air outlet and

light-trap. Notice direction of air flow and also notice how

the lid fits the tray.

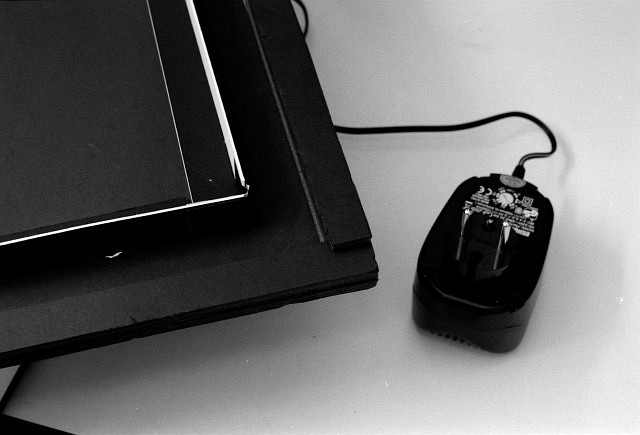

- The lid. The lid is an important part as well,

and must be light safe. Below is a detail of the lid. Notice

foam strips and black matting carton is used to make it light

safe. One full U-turn effectively blocks light. This is less

than the two full U turns in the air in- and outlet, but remember

the ventilators will effectively cause underpressure inside

the box, sucking the lid on top of the tray!

Detail of the lid of the box. Notice the

black matting carton and foam strips used to create an effective

light block. Also visible the 12V transformer powering the

ventilators.

- The final part of the drying box are the glass

plates. In the above pictures, you can see them stacked on

top of each other, separated by the glued-on aluminium U beams.

The U-beams effectively "interlock", keeping the

glass plates from sliding on top of each other, ruining the

coated papers.

You're done! Plug in the power and go! Since there

is no heating, it will take several hours to half a day to

dry the coatings, but excess water is effectively sucked out

by the ventilators and it is a huge improvement over using

paper boxes. To avoid buckling of papers that I intend to

coat, I pre-soak and dry them on the glass plates using water-color

tape before I effectively coat them. This will give perfectly

flat coated papers. Especially these pre-soaked papers need

a long (about 8-12 hours) drying time, while the emulsion

coated papers, with much less water in them, will dry much

quicker.

|